Total : 0

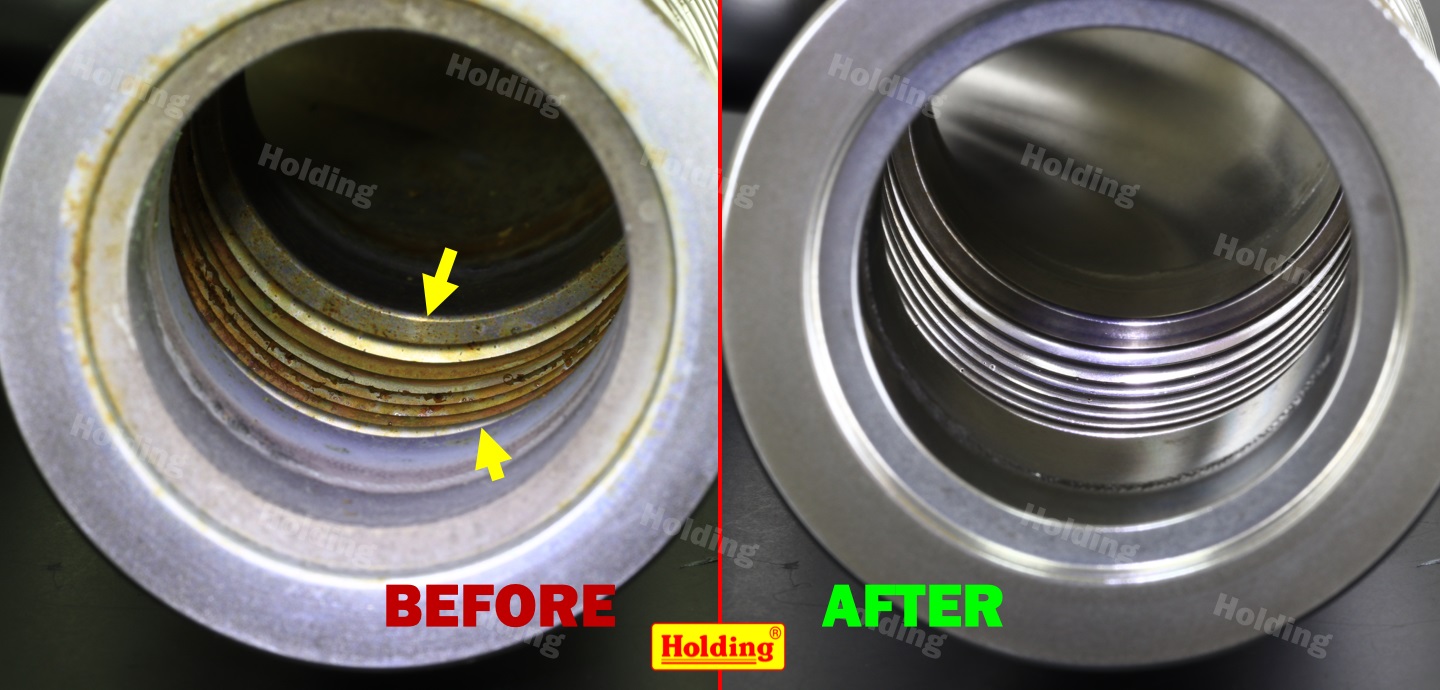

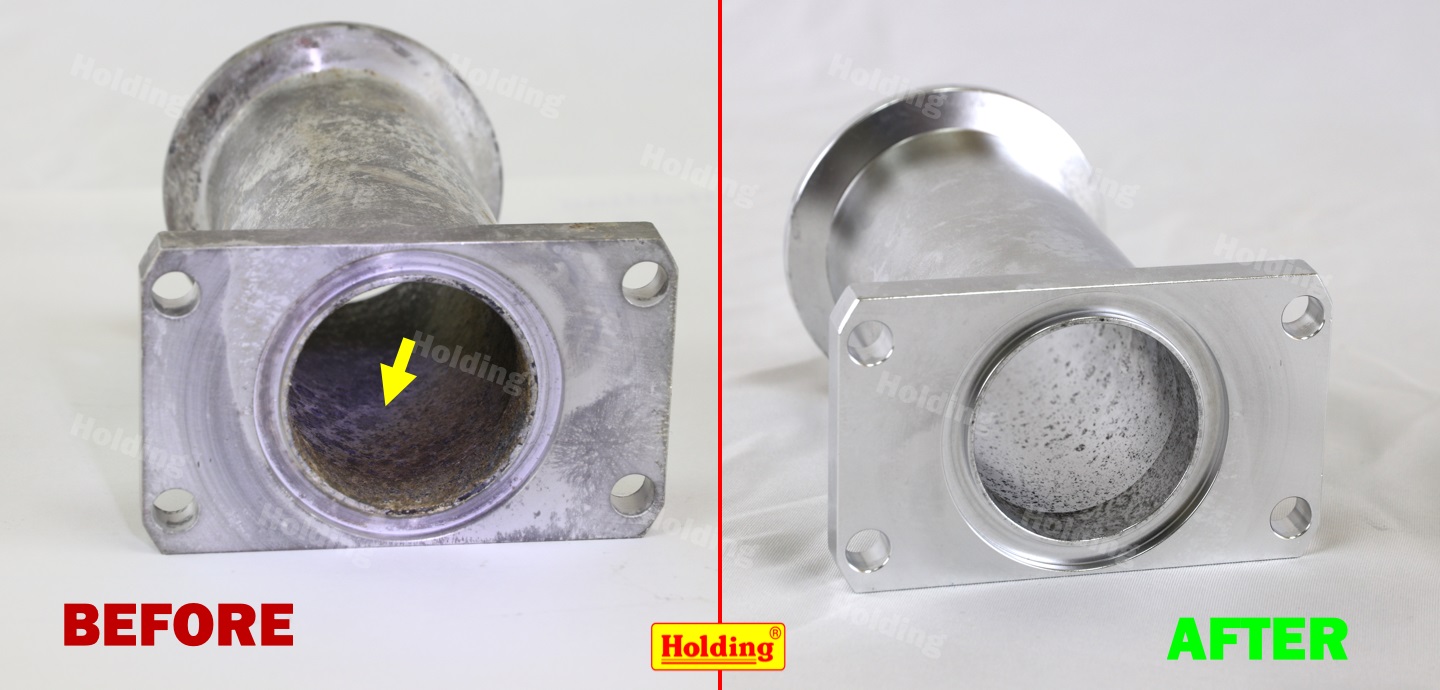

Semiconductor Parts Clean

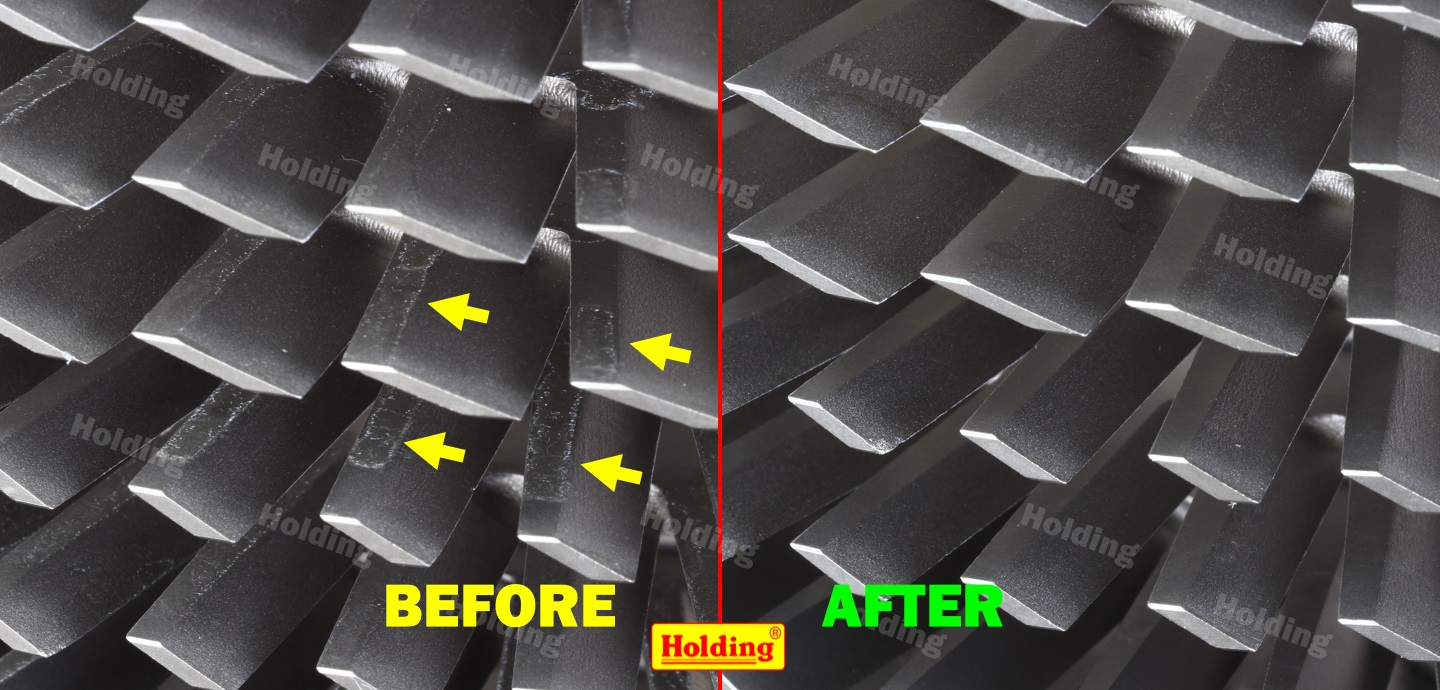

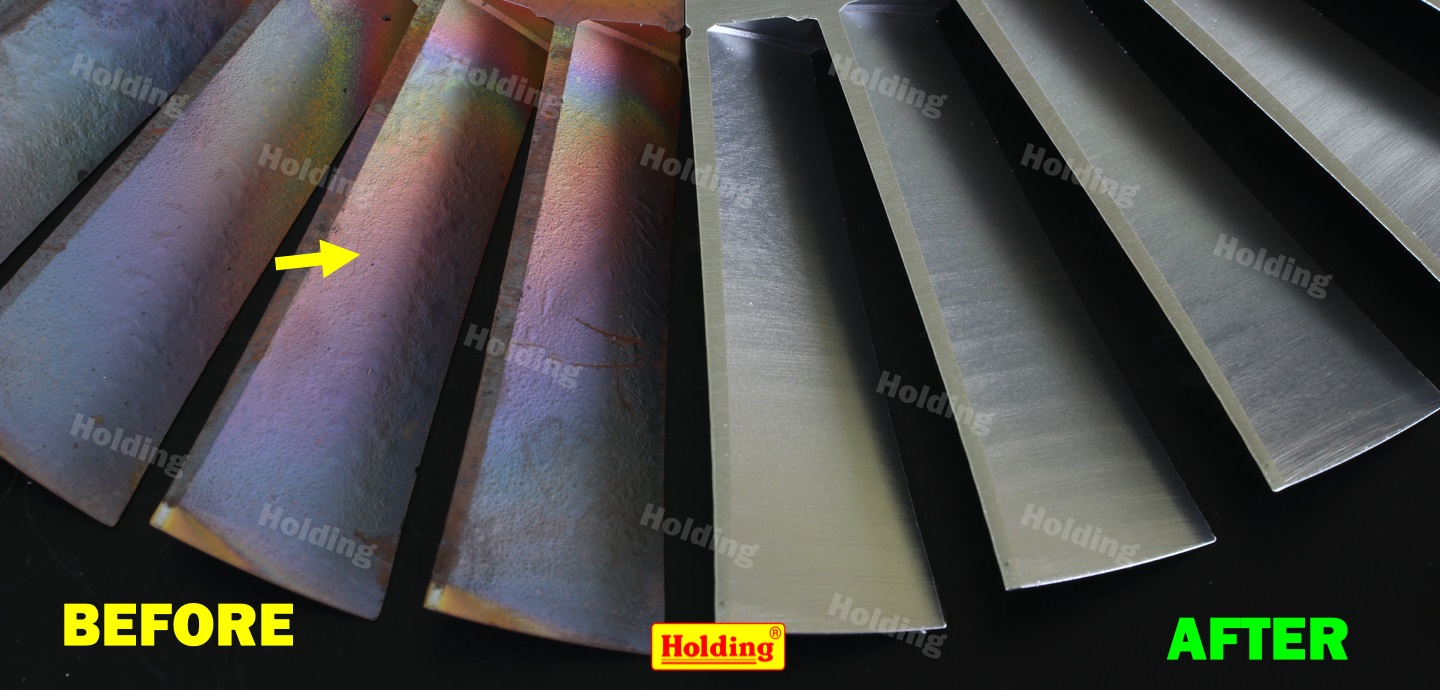

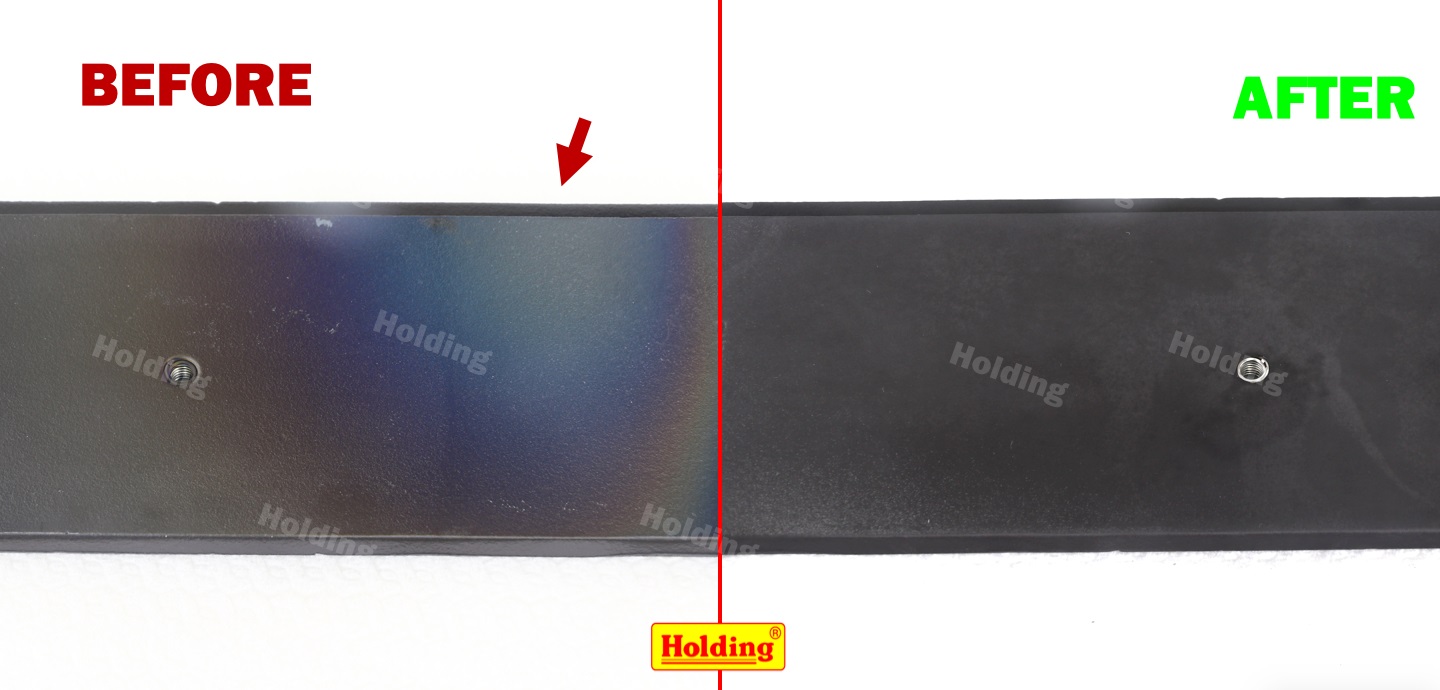

The sPINner uses patented magnetic technology to drive stainless steel needles, like fluid steel brushes. Clean every corner of the equipment parts without dead ends, never hurt the substrate, never deform.

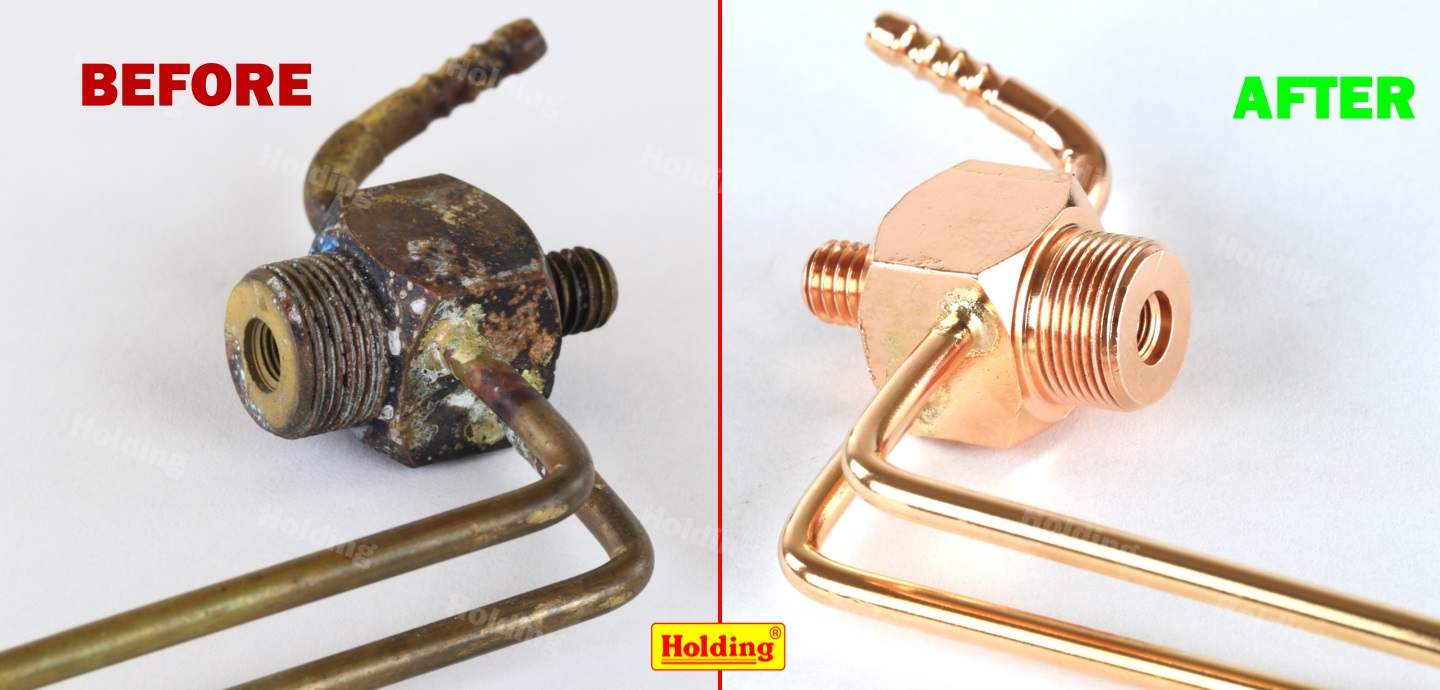

Suitable for cleaning/regenerating semiconductor equipment parts, PUMP parts, water, and oil pipelines.

The characteristics of magnetic grinding technology are as follows:

- Remove process deposits and surface coatings on the equipment without damaging the substrate.

- Fast speed, batch processing, about 10~15 minutes to complete, high yield.

- Can replace sandblasting and chemical liquids, only use general cleaning liquids, no environmental protection discharge and waste liquid recycling problems.

- There is no dead corner, it can reach deep into the inner hole and slit of the workpiece, such as the blade of PUMP, which can be thoroughly cleaned.

- Simple operation, no need for professionals.