About Demag-S

The Demag-S stationary demagnetizing machine is the latest product of Holding in 2020. It is designed to solve the demagnetizing problem for heavy, large, and long workpieces which are difficult to be moved on the conventional demagnetizers.

Features

* Demagnetization can be completed in about 10 ~ 15 seconds.

* Patented low frequency attenuating & alternating magnetic field with strong penetration power. Able to demagnetize thick and solid workpiece.

Why do we need Demag-S ?

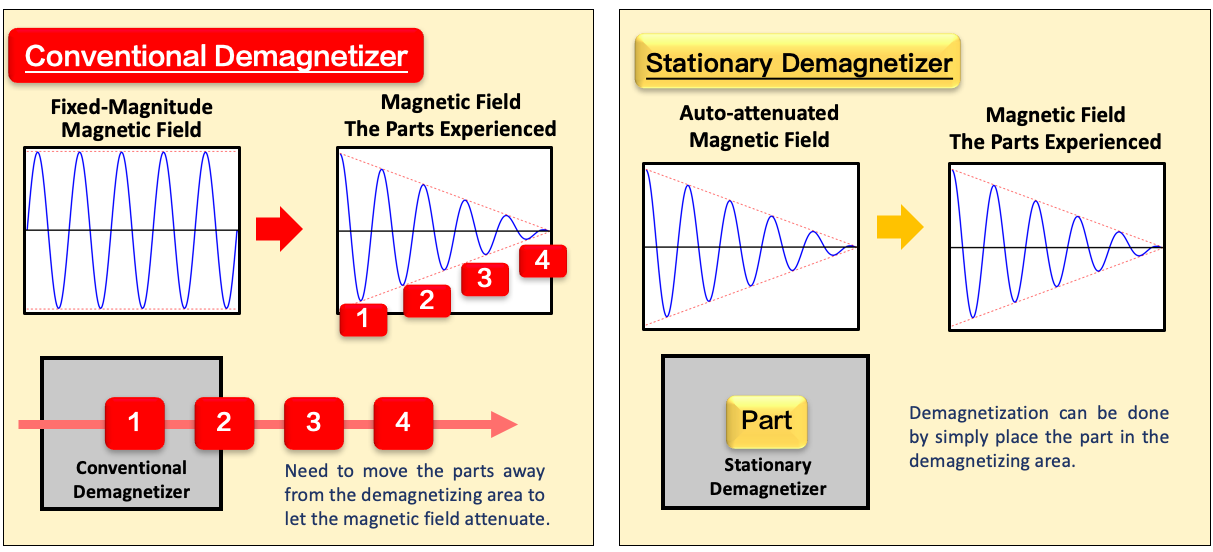

The conventional demagnetizers directly pass the AC power through the coil to generate an alternating magnetic field with a fixed amplitude. While demagnetizing, the workpiece must be passed through the alternating magnetic field and be moved away to ensure a good demagnetization performance.

However, for heavy workpieces, the demagnetization magnetic field will generate a strong attractive force to the workpiece, making it very difficult and dangerous to pass the workpiece through the demagnetization magnetic field.

In addition, for large and long workpieces, the whole workpiece can not pass the demagnetization field at the same time. Therefore, the magnetic domains that have been disturbed by the demagnetizer can be magnetized again because of the other parts that have not been demagnetized.

Principle of DEMAG-S

The patented Demag-S uses a special power modulation circuit to generate a low-frequency and gradual alternating magnetic field, which emulates the effect of the conventional demagnetizer. Its technical characteristics are as follows:

1. Auto-attenuated alternating magnetic field:

Simulate the alternating magnetic field that gradually decays as the workpiece moves away during traditional demagnetization.

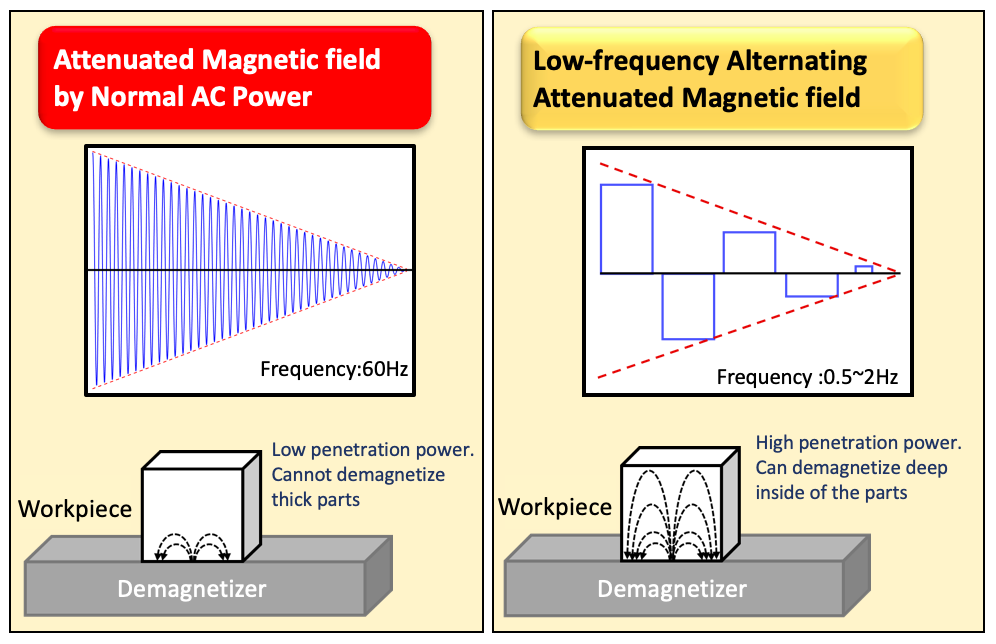

2. Low-frequency alternating magnetic field:

In addition, the static demagnetizer can also reduce the frequency of magnetic field alternating and enhance the penetrating capability of the demagnetizing field. Solid and heavy workpieces can also be demagnetized thoroughly.

3. Optimized design according to the geometric characteristics of the workpiece:

The static demagnetizing machine optimizes the arrangement of the coil and the demagnetizing field waveform according to the geometric characteristics of the workpiece. Specifically, we have developed three models for rod-shape, plate, and ring-shaped workpieces.

Models

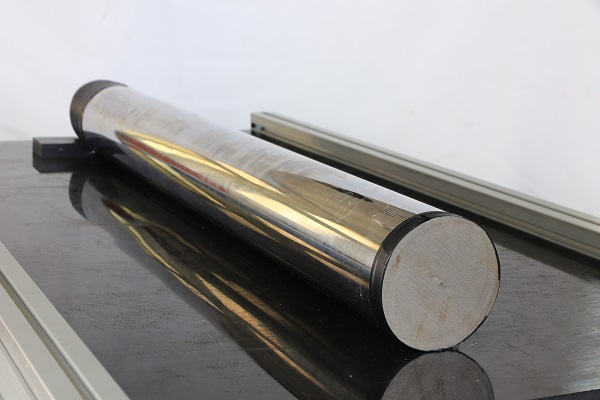

1. Demag-S for long workpieces:

Suitable for long workpieces with a length of more than 300 mm and a diameter of less than 120 mm, such as steel rods, steel tubes, spindles, slide rails, etc.

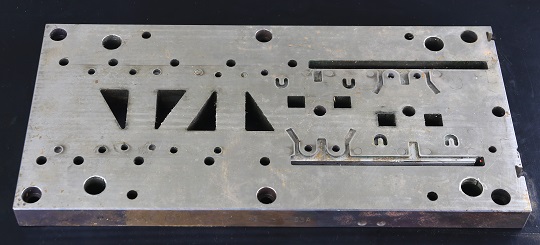

2. Demag-S for plate workpiece:

Suitable for plate workpieces with a length and width of more than 150 mm, especially suitable for molds.

3. Demag-S ring-shaped workpieces:

Suitable for ring-shaped workpieces with a diameter from 150mm, such as steel pipes, connecting rings, etc.