Menu

- ABOUT

-

Products

- All

- sPINner: Magnetic Deburring & Polishing Machine

- Semi Equipment Cleaning Machine

- Demagnetizer

- Demag-S : Stationary Demagnetizing Machine

- Chuck controller and Demagnetizer

- Oil Skimmer

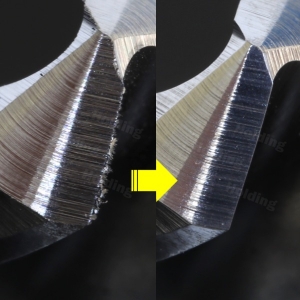

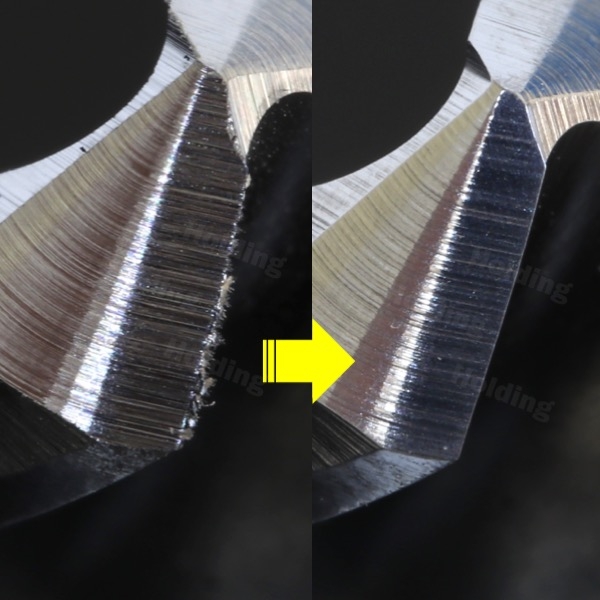

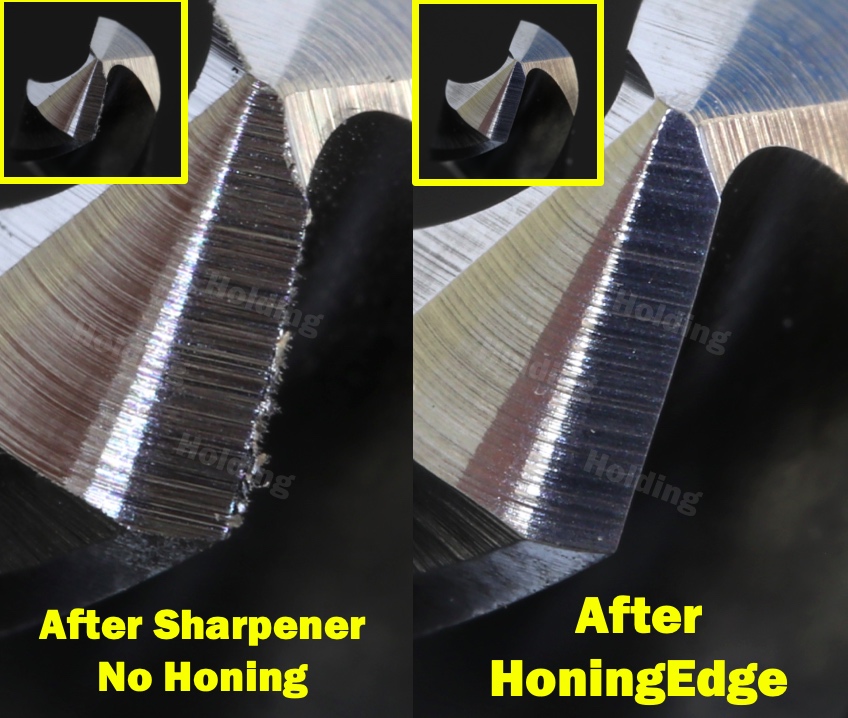

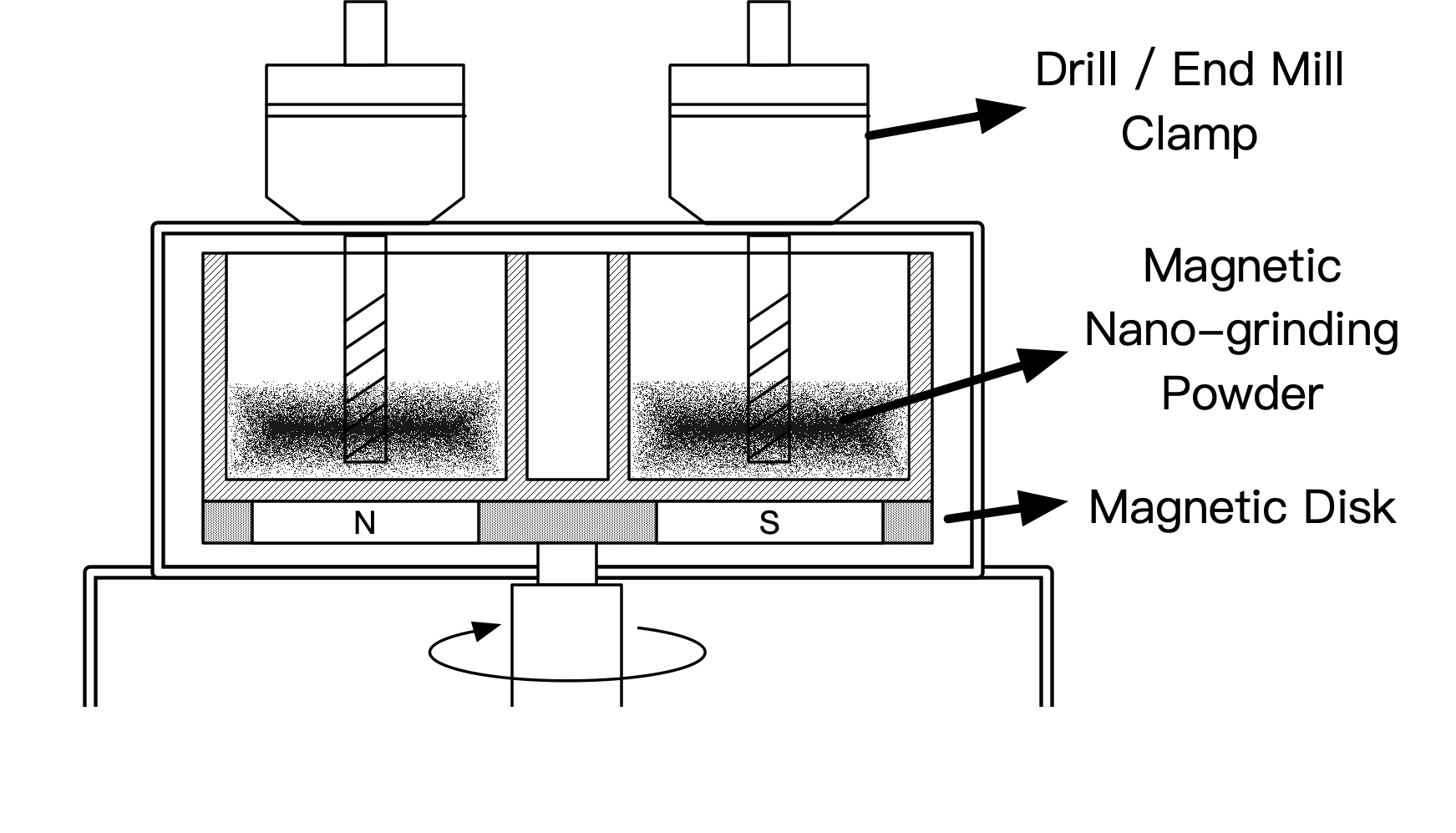

- HoningEdge: Magnetic Tools Honing Edge Machine

- RFID for Smart Tool Management Chip

- New Products

- Mold Cleaning Machine

- E-catalog

- New Products

- Contact

- News

Products

Subscribe Newsletters

footer-nav1

side-nav

Contact Us

-

NO.31, CHAOGUEI RD., TAICHUNG 407, TAIWAN

© 2020 Copyright © HOLDING ELECTRIC CO., LTD .