About Oil Skimmer

No More Floating Oil!

Floating Oil Problem on Cutting Fluid

In CNC machine, the floating oil problem on the cutting fluids happens frequently. There are many sources of oil, such as slide oil, rust preventive oil, or hydraulic oil leakage. When oil leaks into the water-based cutting fluid, it floats on the surface and gradually blocks out the air. Over a long period of time, the cutting fluid is liable to rot due to the growth of anaerobic bacteria and produce a foul smell. Cutting fluids also tend to become sticky, causing processing problems.

Oil Skimmer Principle

Our oil skimmer uses a lipophilic belt made of special fiber or a special silicon tube to absorb oil with higher viscosity. On the other hand, water-soluble cutting fluids are not adsorbed because of differences in viscosity and surface tension. Both the belt and the tube are designed to perform continuous oil skimming in a circular way. The belt or tube that absorbs oil is driven by a motor, and the oil is brought up and scraped off in the upper trough. Finally, the oil flows into the waste oil recovery barrel along the oil pipe. In this way, the oil skimmer removes the floating oil continuously.

1. Prevent cutting fluid from spoiling due to bacteria and prolong its lifetime.

2. Reduce workpiece corrosion, rust and surface damage.

3. Improve machining accuracy and extend tool lifetime.

4. Reduce the amount of waste oil and wastewater treatment to prevent

environmental pollution.

Holding Oil Skimmer Features

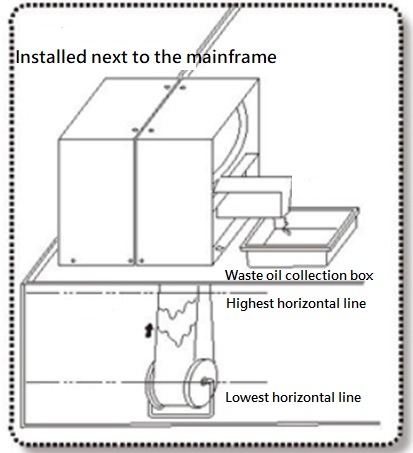

We have two types of oil skimmers, the belt type and tube type. The belt type one is designed for high oil removal capability, while the tube type is designed for installation in narrow spaces. The machine can also be equipped with a 24-hour timer that can automatic switching on/off the device.

The oil skimmer has the following freatures:

1. Low operating cost, no consumables required.

2. Small size, lightweight and can be installed in limited space.

3. Special belt/tube design, good heat and chemical tolerance.

Application Scenario

1. Removing the oil on the cutting fluid of CNC machines or special-purpose machines.

2. Removing the oil on the grinding fluid of surface grinders, cylinder grindings, or other grinding machines.

3. Removing the oil on the cleaning fluid for workpeices.

4. Separating and recovering the floating oil from wastewater discharged from a factory, reducing the cost of wastewater treatment.