About HoningEdge

Make Tools Perfect Again

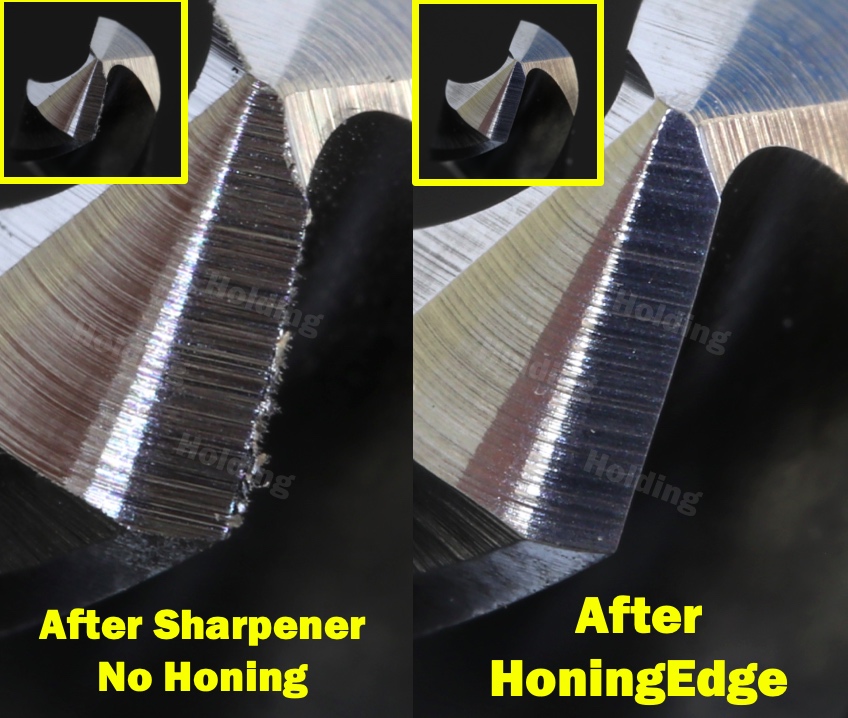

When drills and end mills are no longer sharp, sharpeners (drill / end mill grinding machines) are often used to trim the blunt tools. However, the grinding wheel of the sharpener are rough and usually leaves many small burrs and cracks on the tool edges. As a result, the machining accuracy is reduced, the tool life is shortened, and tool is prone to chip after resharping.

The HoningEdge - Magnetic tools honing edge machine - can helps!

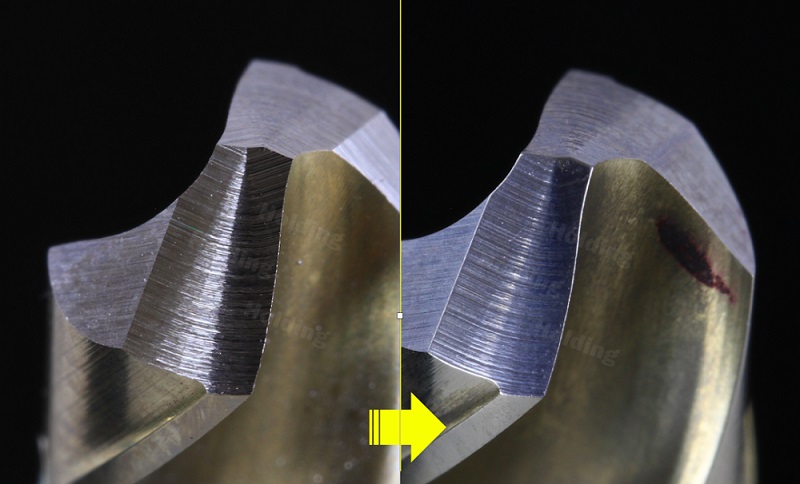

Please look at the pictures below. The tools treated by the HoningEdge can see amazing improvements in just a few seconds!

H.S.S Drill HoningEdge Case

Tungsten CarbideDrill HoningEdge Case

Effects of HoningEdge

HoningEdge can bring you the following effects in a short time.

1. Remove burrs caused by tool sharpeners.

2. Trim the chipped and sawn edges of tools due to tool sharpeners.

3. Achieving a consistent rounding, making the blade smooth, sharp, and more durable.

4. Improve the machining accuracy & surface roughness the workpiece.

5. Increase tool lifetime and reduce the probability of chipping. From real measurement, the HoningEdge can increase the tool lifetime by up to 65% comparing to the tools that have been sharpened only.

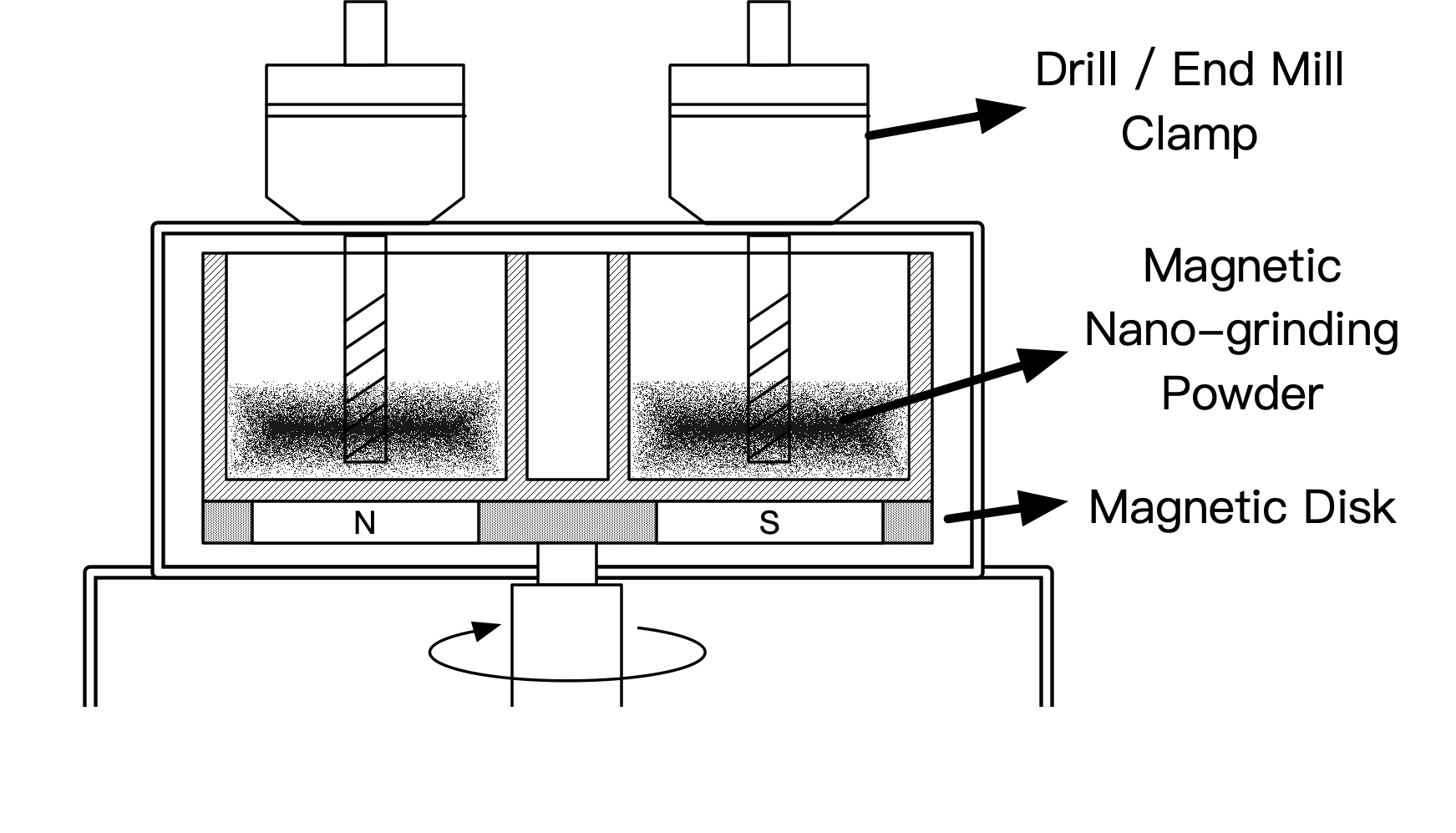

How

HoningEdge generate a magnetic field to drive hard magnetic nano grinding powder, and It produces a fluid-like vortex motion of the powder to grind the drill and end mill blades. It achieves the effects of burrs, trimming and passivation in a short time.

How to Operate

Just 4 simple steps to make your tool perfect again.

1. Insert the tool into the clamp (a standard accessory).

2. Using the tool length setting base on the HoningEdge machine to adjust the insertion length, and then tighten the clamp.

3. Turn on the machine and insert the tool into the grinding slot, press down to start grinding.

* For H.S.S. tools, it takes about 10 seconds.

* For tungsten steel tools it takes about 1 ~ 2 minute.

4. After finishing, please remove the tool while the machine is running to eliminate the magnetism on the tool. Then use the included brush to brush the magnetic powder attached to the tool back into the machine.